5 Common Barnett Scorpion Clutch Problems and Their Fixes

The Barnett Scorpion Clutch is a high-performance kit that optimizes manual gearbox vehicles by ensuring even friction and pressure distribution among clutch plates. Despite its benefits, the clutch may encounter typical issues like any other model.

Malfunctioning engagement points, wear and tear of the clutch components, and insufficient clutch spring tension are a few of Barnett Scorpion’s problems. The clutch slips, chatters, drags, or becomes hard to shift due to these problems.

If you’re also facing these issues with your Scorpion clutch, this guide just might be the perfect solution for you.

Troubleshooting and Fixing Barnett Scorpion Clutch Problems

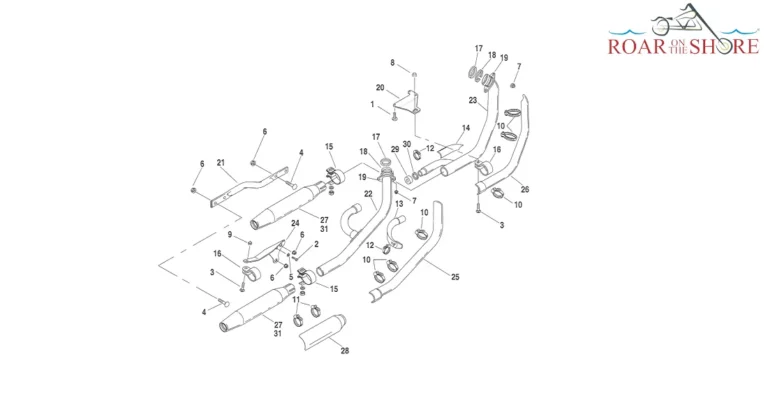

This Clutch Kit consists of a derby cover, springs, and a clutch basket. Troubling issues with any of these components can cause problems with clutch engagement and actions.

Let’s take a look at all of the problems that users have faced with a Scorpion clutch up until now.

1. Engagement Point Malfunction

For a clutch, the engagement point is the element which engages the position of the clutch lever right where the clutch plates are in contact.

Friction force, material and the angle of the engagement affect the engagement point of the clutch.

If the material used for friction is too hard, the engagement point increases.

As a result, the clutch becomes harder to engage. There is a noise, squeal, or squeak every time you try to take off.

The engagement point can also get farther away until the lever is 3/4th out. Maneuvering the bike at a slow speed becomes harder in that case.

In some cases, using a soft friction material makes the clutch easier to engage. Adjust the engagement point in the proper way to fix it. If it’s still hard to engage, follow these instructions:

- Remove the clutch plates.

- Get new damper springs and seats and install them.

- Install a thin friction plate.

- Reinstall the original clutch plates.

2. Clutch Slippage

Clutch slippage is the problem that appears when you fail to disengage or engage the transmission. The bike easily slips out of gear and faces difficulty while changing gears.

Gurgling noise, poor attempts at staying in gear during acceleration, and vibrating clutch pedals are the symptoms of clutch slippage.

Clutch slippage can be caused by a variety of things. It can be due to worn or warped friction or metal, pressure plates or hubs, stretched or flexed cables, defective hydraulic system, or inappropriate actuator adjustment.

The first course of action to fix clutch slippage is to adjust the clutch position. However, it is very rare that only this will eliminate the slippage.

In most cases, you’ll need to replace the clutch. Contact an expert mechanic to help you with this replacement.

3. Inadequate Clutch Spring Tension

Adequate clutch spring tension is necessary for successful clutch performance. Weak or worn-out springs eventually lead to clutch slippage.

If the springs are too heavy, they stress out the center hub, case covers, or clutch activators themselves. They can also damage the pressure plate and stretch out the cable.

The clutch lever becomes overly stiff, so it puts pressure on your left hand. It creates trouble while shifting gears, as it will require more force to pull.

Tightening the springs will increase the spring tension, but making them too tight will also make them stiff. Doing this won’t always improve the clutch’s performance.

Alternating the standard springs with heavy duty springs is a good fix for fine-tuning your clutch.

The springs must be properly positioned when alternating them with an even number of springs. Replace the worn out springs with new ones.

Read Also: E3 Spark Plugs Problems – Troubleshooting & Fixing

4. Release Bearing Surface Wear

When the release bearing units start to wear out, the clutch becomes almost impossible to operate.

The surface begins to wear out due to the constant friction between the drive shaft and the release bearing units. Improper lubrication is also the cause of this wear.

The release bearing surface wear can be noticed when you feel vibrations coming from the clutch pedal. Because of this wear, the clutch pedal becomes too stiff when you press down on it.

Replace the damaged or worn out release bearing units to fix this problem. Keep the bearings properly lubricated to avoid excessive wear.

Check the transmission fluid level and refill it if necessary as it keeps the friction to a minimum.

Read Also: 5 Most Common Star Tron Problems What You Need To Know

5. Clutch is Hard To Shift

When you notice the Scorpion clutch being too hard to shift, there could be a few possible catalysts for this.

If the main chain or belt or the rear wheel’s drive chain is incorrectly adjusted, the clutch becomes stiff.

Transmission or gearbox issues also cause this problem. Another reason for having trouble shifting the clutch is poor quality of the primary oil used in the vehicle.

The cables might need adjustments to make the clutch shift. Make sure the oil used is not too old or burned. Fill the tank with the correct level of new oil to solve a huge part of the problem.

Check for any kind of leak around the clutch cylinders. Adjust the chains connected to the clutch by following the manual or getting expert help.

Tips To Prevent Barnett Scorpion Clutch Issues

Most of the problems with the Scorpion clutch insides are due to wear and tear, adjustment issues, or improper handling of the components.

So, by creating routine maintenance for the clutch, it is possible to eliminate most of the problems.

Build up a maintenance routine with the following tips in order to prevent Barnett Scorpion issues:

- Purchase the right clutch kit for your own Barnett in order to minimize the problems.

- While getting springs, make sure they match the requirements of the clutch.

- Heavy duty springs are 10%-20% more effective than OEM springs, so go for them.

- Regularly check the oil level and condition of the clutch.

- Use silicone material while repairing the clutch components, as it meets all the requirements.

- Clean the mechanisms of the clutch with a toothbrush regularly to prevent excessive friction.

- Check for wear and tear in the clutch components regularly.

- Lubricate the clutch with synthetic or hydraulic oil periodically to reduce friction and wear.

- Use a Barnett Scorpion hub puller to check the clutch system every time before using the vehicle.

Read Also: 5 Common Shoei Neotec II Problems [Troubleshooting and Fix]

FAQs

In order to deal with the Barnett Scorpion clutch problems, the more you know about them, the better. So, let’s take a look at some more information regarding this renowned clutch.

What Oil Is Good For The Barnett Scorpion Clutch?

Any primary standard formula oil suitable for wet clutches is a good choice for the Barnett Scorpion. ATF oil with type F and Dexron are great oils to provide proper lubrication. Refrain from using any HD formula oil for the clutch.

How Much Will It Cost To Fix Barnett Scorpion Clutch Problems?

It can cost you about $949-$1206 to fix Scorpion clutch problems. The best option is to buy the Clutch Basket Rekluse RadiusX Clutch Kit for $949. The other kit options will cost up to $1206.

What Is The Proper Clutch Adjustment?

To find the proper clutch adjustment, pull up the clutch cable to a point where the clutch fork is engaged. When the fork engages, that’s the ideal clutch adjustment level. Tighten the nuts by keeping the cable in the same position.

Conclusion

Barnett Scorpion Clutch Kit has high-quality components and a simple design, which is great for racers. The lightweight construction and improved pedal engagement of this clutch make it a user favorite.

The ability to withstand extreme weather and rust resistant build of this make it more durable. The slight problems you have to face with the clutch are avoidable with proper maintenance and care.

Once it reaches its full potential, you can shift gears quicker and brake harder on the track. If you still can’t figure out the problem by yourself, contact a professional for help and get it fixed soon.

![Harley Davidson Flush Mount Gas Cap Problems [Explained]](https://www.roarontheshore.com/wp-content/uploads/2023/06/Harley-Davidson-Flush-Mount-Gas-Cap--768x386.webp)

![Harley Davidson Power Vision Tuner Problems [Solved]](https://www.roarontheshore.com/wp-content/uploads/2023/06/Harley-Davidson-Power-Vision-Tuner--768x427.webp)